Maximizing efficiency is at the core of every business. In manufacturing, it can mean boosting productivity, updating systems, cutting costs and taking other measures to improve throughput and maintain or increase profitability.

Considering that operational costs and the business’s bottom line are in the picture, concerns about how to improve efficiency in manufacturing remain a big part of every facility’s business strategy. To ensure team members operate in line with your efficiency standards, you must develop strategies that support your performance goals.

Manufacturing is an extensive process that relies on your capacity to maximize operations and drive profitability in the workplace. Since your level of manufacturing efficiency is tied to profitability, it affects production costs, customer satisfaction and competitive advantage.

How you boost efficiency in your manufacturing process will result in tangible benefits in the following areas:

The manufacturing industry faces numerous challenges that impact overall production. While some of these challenges are out of manufacturers’ direct control, such as geopolitical crises, political reforms and climate shifts, many are tied to inefficient processes. Some of the common inefficiencies manufacturers face include:

Improving efficiency in your facility requires a comprehensive review of your strategies and a step-by-step process that irons out production systems while maximizing resources. You want to identify areas that consume key resources and evaluate their output.

Here are strategies that can help you work toward improving manufacturing efficiency:

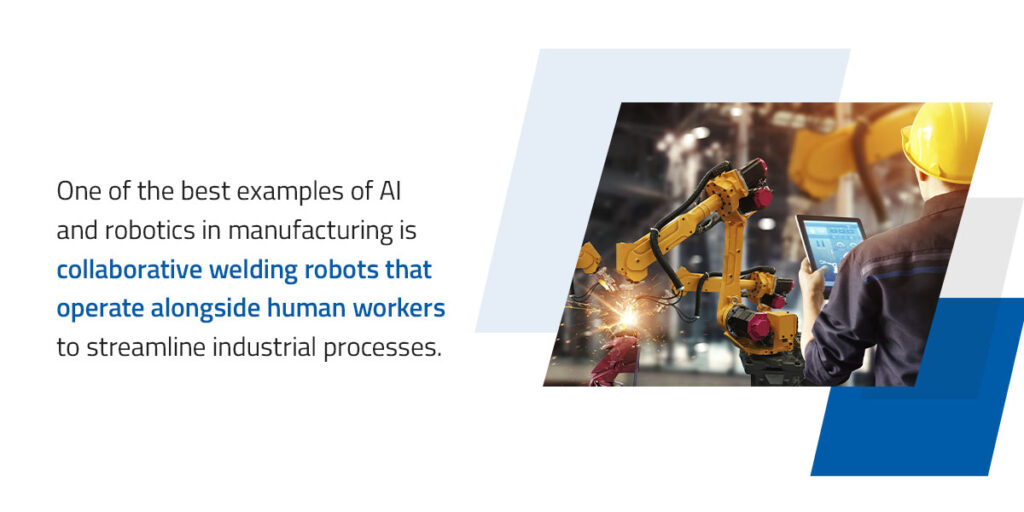

Artificial intelligence (AI) and automation have resulted in rapid digital transformation. In manufacturing, these technologies are part of the next-level advancement you may want to embrace to keep up with the industry. As automation replaces many tasks that are often completed manually, it speeds up these processes and reduces human error, adding a layer of efficiency that is impossible without technology.

You can automate your systems through robots and by integrating AI-supported software. One of the best examples of AI and robotics in manufacturing is collaborative welding robots that operate alongside human workers to streamline industrial processes.

Equipment is a costly and vital component in any manufacturing facility, impacting the manufacturer’s bottom line. Proper maintenance extends equipment life, reduces downtime, decreases repair and operational costs, lowers accident risks, and streamlines operations. While you may be taking measures to ensure proper maintenance, using predictive maintenance techniques will take your efficiency to the next level.

Predictive maintenance software uses can use tools like machine learning to determine the condition of your equipment and predict when potential problems may occur. This information allows your team to take preventive measures and correct the flagged issues.

Quality control and assurance are processes that keep your plant in line with your product and service expectations and regulatory requirements. Quality control also plays a role in efficiency. Some of the popular techniques you can employ to monitor and maintain quality for improved efficiency include:

Quality control and assurance can help you oversee and improve performance and effectiveness throughout the manufacturing process, resulting in higher overall equipment effectiveness.

Combining inventory management and time management can help improve efficiency on the production floor. Here’s a breakdown of these two considerations:

Maintaining overall efficiency in your facility requires a strategy for managing inventory, such as using smart systems for digital inventory tracking. These systems should improve reaction to market changes, allowing you to adjust stock levels and other aspects of the supply chain. Digital solutions like automated inventory management software can streamline the supply chain through capabilities like demand planning, mobile integration and barcode scanning.

These strategies can improve stock efficiency, eliminating overstocks and stockouts. You’ll know when to use bulk quantities to boost cost savings and maintain supply.

Inventory management is closely linked to time management. With efficiency principles like just-in-time inventory management, also known as lean management principles, your plant can strike a fluid balance between production volume and inventory levels, allowing you to free up cash flow and labor. As a result, you improve costs and save time.

In addition, your facility can improve time management during operations by training employees on effective time management. Key components of time management include staying organized, working as a team, communicating clearly and prioritizing value-added tasks.

Understanding how to improve efficiency in manufacturing can be the key to your facility’s success. Overall, you want to consider automation technologies, predictive systems, quality control and inventory and time management practices to make the most impact.

Given today’s unpredictable industry demands, working with a solution-driven partner can be the tool you need to strengthen your operations and maintain growth. At Meritus Gas Partners, we support our customers with resources and corporate services to help them deliver.

Having access to a reliable manufacturing distributor, whether you need materials processing gases or safety equipment, is a key part of creating a more efficient facility. Learn more about our network of partners and contact us to get started with industry-specific solutions.