Enhance your welding operations with the advanced capabilities of the MOD-WELD collaborative robots (cobots) from APT Manufacturing Solutions.

APT Manufacturing Solutions is a leader in industrial automation, specializing in integrating cutting-edge robotics and welding technologies. Regarding industrial robots and models, MOD-WELD cobots stand out for their flexibility, precision and user-friendly interface. They integrate seamlessly with FANUC Robot options and Miller Auto-Continuum™, offering versatile and robust welding solutions that cater to various industrial applications.

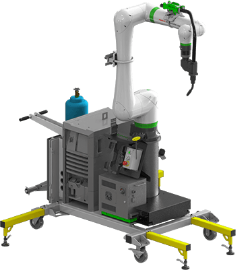

The MOD-WELD Cobot MAC Cart is a highly versatile and mobile collaborative welding solution. It is designed around the FANUC CRX-10iA/L robot and delivers flexibility, precision and efficiency.

Various table accessories are available to enhance functionality and efficiency, including:

The MOD-WELD Cobot MAC Traveler is a groundbreaking product by APT Manufacturing Solutions. It is a mobile, flexible welding solution built around the FANUC CRX-25iA robot. This design provides precision and efficiency in a wide range of industrial applications.

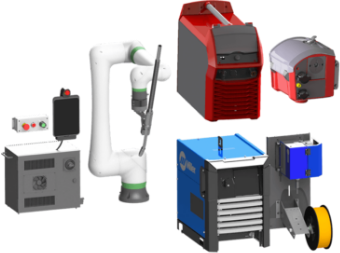

The MOD-WELD Cobot MAC Bundle by APT Manufacturing Solutions offers a complete welding automation solution. Featuring the FANUC CRX-10iA/L or CRX-25iA collaborative robots, it is perfect for manufacturers seeking a comprehensive, flexible and efficient welding solution.

Automated welders from APT Automated Solutions come with exemplary capabilities and benefits.

The MOD-WELD cobot delivers improved productivity, safety and consistency, making it invaluable in modern manufacturing. It handles repetitive welding tasks with precision, reducing errors and increasing throughput.

Robotic welding is significantly faster and more consistent than manual welding. The MOD-WELD cobot offers rapid, consistent welds, optimizing manufacturing timelines.

Investing in a MOD-WELD cobot reduces labor costs, minimizes downtime and increases output and quality. This leads to a substantial ROI.

MOD-WELD cobots reduce operational expenses by performing the work of multiple employees, streamlining processes and reducing labor costs.

Achieving top welding quality and versatility in industrial applications is crucial for maintaining high standards and meeting diverse manufacturing needs.

Cobots from APT Manufacturing Solutions deliver top-notch quality through precise control and consistent performance, which is vital for maintaining high manufacturing standards.

These cobots are versatile, handling various welding applications regardless of complexity. Their adaptability accelerates project timelines and improves overall efficiency.

At Meritus Gas Partners, we partner with highly skilled, independent suppliers across the country, ensuring you have access to the best quality welding supplies and equipment, industrial gases and services. Our distributors offer the advantage of nationwide resources coupled with the local knowledge and personalized service smaller organizations can provide.

A variety of supplies are available through our distributors, such as:

Services include:

Meritus Gas Partners prioritizes our distributors and consumers — we increase opportunities for reliable and trustworthy businesses and connect consumers with companies they can count on for high-quality products and services.

Revolutionize your manufacturing with ready-to-deploy MOD-WELD cobot solutions from Meritus Gas Partners. We offer rapid two- to three-week lead times, nationwide availability, expert guidance and comprehensive support. Contact us today for orders or inquiries.