Collaborative robots, also known as cobots, have revolutionized the manufacturing industry with their intuitive programming, affordability and barrier-free operation. Their use in the manufacturing sector continues to rise, thanks to their ability to automate material handling, material removal, maintenance, quality control and more functions.

The collaborative robot market was valued at $1.2 trillion in 2023 and is projected to triple by 2030. Having these robots on your team is a cost-effective way of increasing productivity. However, to ensure they work as expected and you can reap their benefits, you need to maintain them properly.

Like any other machine or equipment, robots require preventive maintenance. Reliability and precision are non-negotiable in the manufacturing industry, and you want your robots to always produce the expected results.

Regularly conducting preventative maintenance will help you avoid issues that can affect the cobot’s performance. Specifically, preventative maintenance can address the following issues:

Performing preventative maintenance can lower the chances of your cobot breaking down or showing signs of damage. As a result, neglecting this maintenance means the robot may break down when you least expect it. The following signs can indicate that your cobot needs maintenance or repair:

If it’s been a long time since you last maintained the cobot, you don’t need to see any signs to do maintenance. You should inspect the cobot as soon as possible and perform maintenance if necessary. At that point, it’s important to establish a routine maintenance plan so you can prioritize the care of your cobot.

Without a scheduled plan, skipping or forgetting preventative cobot maintenance is easy. This is why you should have a maintenance plan that includes scheduled periods when specific types of maintenance are required. Take the following steps to develop, follow and update your plan:

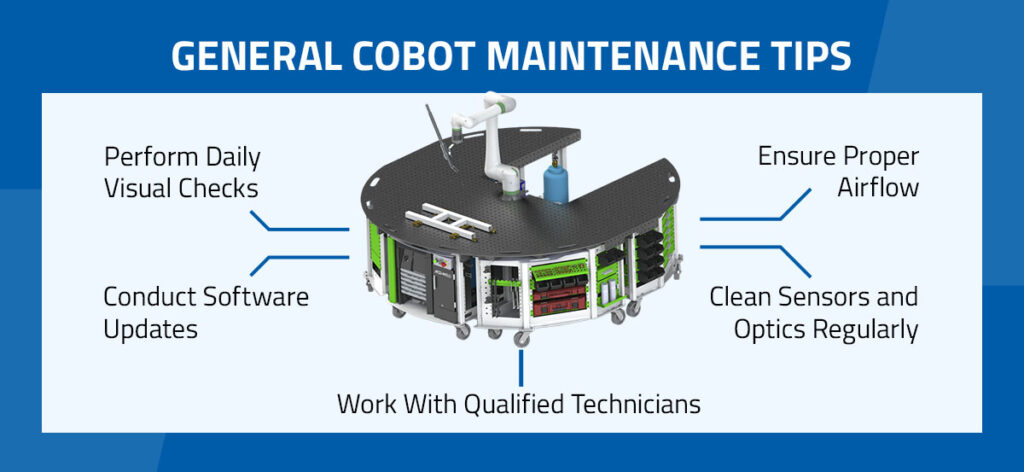

As part of your maintenance plan, you’ll want to include specific checks and tests to ensure the cobot is operational and identify any issues. The specific repairs you do will depend on your cobot’s make and model, so always consult the operator’s manual to form the foundation of your approach. However, general checks like the following are also important:

Perform daily visual checks on the cobot for any possible damage or signs of impending damage. This step should be an integral part of your team’s process so you can identify potential issues quickly and before they worsen. For example, you or a team member can visually check the cables and bolts to make sure they’re configured properly

Regular software updates are crucial to ensure the safety of the cobot. In addition, software updates allow for the addition of new operational features. Check out your manufacturer’s recommendations on software updates. A software update may include features that make it easy to diagnose and troubleshoot your cobot and provide the ability to export logs to the manufacturer’s customer support.

Proper airflow is required in a cobot’s controller to prevent overheating, which can cause damage. This damage may compromise the robot’s life span. Clean the cooling fans every three or so months to avoid overheating and keep your cobot running properly for longer.

Optics and sensors are crucial vision tools for cobots. Cobots rely on these tools to move, pick up items and drop them. Ensure the sensors and optics are clean and free of debris or dirt to ensure the cobot’s performance isn’t compromised. Dirty or poorly maintained optics may also make the cobot unsafe to use.

When you need repairs done on the cobot, work with qualified and authorized personnel who can do the work properly and professionally. Attempting to do the work yourself without the right knowledge can result in cobot damage or safety issues for yourself. It’s always better to invest in expert assistance when it comes to maintaining your equipment.