Gas cutting is a method of melting through materials — typically metals — using a combination of gases and oxygen. Comparing gas-cutting gases and techniques can help you find the solutions you need for maximum quality and productivity.

Gas cutting is a key process for producing essential items in many fields, including shipbuilding, construction and medicine. It has a number of applications, from using gas cutting on welding deformations to metal fabrication. There are three main elements to consider when distinguishing between the different types of gas cutting — the highest flame temperature, the volume of gas required for combustion, and the level of heat the combustion produces.

Thanks to their various advantages, five types of gas are commonly used for cutting:

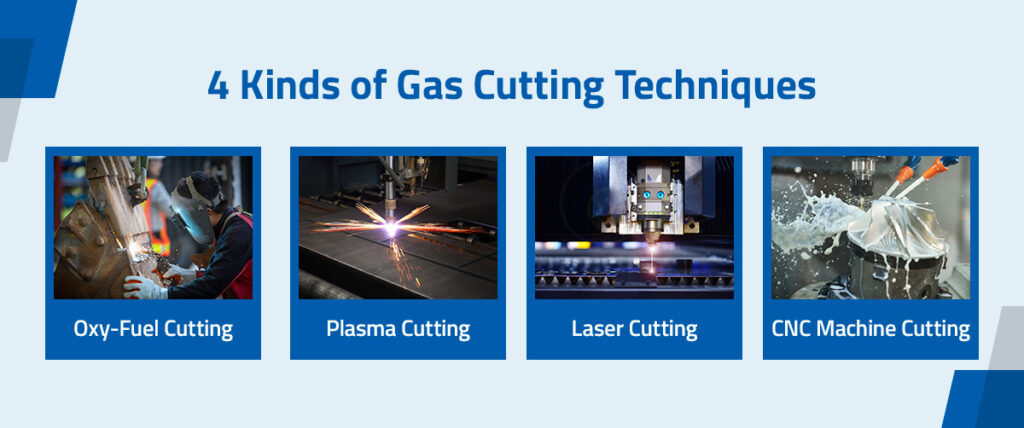

Just as there are multiple kinds of gases used in gas cutting, there is more than one type of gas cutting technique. Here are four of the most common gas cutting systems:

Oxy-fuel is a thermal cutting method that uses fuels like gasoline met with oxygen to make cuts into metal items. The welder preheats the metal below its melting temperature using the fuel and oxygen mixture. They then use a pure oxygen jet to create an oxide of the metal in the preheated area. The exothermic reaction causes a slag, and the oxygen injected into the area blows the slag out of the kerf.

Oxy-fuel systems weigh around 35 pounds and don’t need electricity, so they’re portable and convenient. One of the greatest features of oxy-fuel systems is their versatility. They can be used to solder, cut, weld and gouge. Keep in mind that oxy-fuel systems are only used for applications containing iron or ferrous metals, such as steel.

The type of fuel gas you select determines the cut quality and preheating times. Typically, cutters use at least four basic fuel gases — propylene, natural gas, acetylene and propane. Paired with oxygen, these gases create the metal oxide chemical reaction.

Oxy-fuel is generally better for thicker metals. It can easily cut through steel that’s around 6-12 inches in width. Torchers have greater cutting speeds than the typical hand-held plasma cutting systems, so keep that in mind when working with steels of more than 1 inch in width.

Some systems can cut through more than 20 inches of steel width. They also offer added safety, as some systems come in extended lengths to keep the operator a safer distance from the intense heat and slag. The longer hoses also allow for greater portability.

Plasma is a type of ionized gas that relies on electricity for cutting power. It requires energy and electrically neutral gas to conduct electricity.

Gas and electricity combine in the chamber between the nozzle and electrode, causing the gas to become imbalanced. This process creates plasma gas, and the air pressure buildup forces it through the nozzle. The more energy you add to the cutter, the hotter the arc becomes, which gives you excellent cutting capacity.

Plasma cutters are best for cutting and gouging. They require electrical power, but they can still be considered portable since most job sites have electrical sources readily available. In terms of simplicity, plasma systems are much easier to use than other gas cutting systems and require minimal cleanup.

The average hand-held plasma system can cut through a maximum width of 1 inch. It works on nonferrous metals like cast iron and aluminum. One notable benefit is that it creates minimal slag, which allows for smooth and aesthetically pleasing cuts. This cutting method also saves time and money because, unlike with oxy-fuel, you don’t have to preheat the metal before cutting. It’s also faster with thinner metals and doesn’t create distortion, even when working with stacked metals.

If you’re working with shaped metals, plasma is advisable, as it’s quicker and more precise. Plasma also offers additional safety since it doesn’t expose you to an open flame or require handling explosive gases. However, safety isn’t a major concern if you invest in a cobot for your operation, as it can help prevent injuries and engage safety modes. Contact a Meritus Gas team expert for more information on our cobot equipment.

Laser cutting uses intense energy from a beam of light to rapidly heat and melt through a metal surface. There are two types of laser beams — pulsed and continuous.

Pulsed laser beams use high-energy laser beams in short bursts. The compressed pulses allow the laser to shoot high-energy beams. Continuous laser beams create a stream of light beams without taking intermittent breaks, cutting for a longer period at a time.

Once the laser beams melt through a particular section of a metal surface, a high-pressure gas like oxygen is used to blow away excess molten material. This process gives you a smooth, clean final cut.

Laser cutting offers many benefits compared to traditional cutting techniques. Its no-contact nature reduces maintenance costs. You can also create intricate designs with high-quality edges, no slag and a neat finish. The narrow kerf width allows for low wastage and maximum cost-effectiveness. Laser cutting is quick and precise, making it popular in various industries, including aerospace and automotive.

One aspect to consider is that most laser-cutting machines’ cut depth is typically limited to under an inch in metal thickness. An expert tip for attaining low surface roughness, small kerf width and angle and minuscule heat-affected zone is to opt for a low laser power with a high cutting speed and finish it off with medium gas pressure using nitrogen as an assist gas.

Computer numerical control (CNC) technology uses specialized software to improve precision and speed. It automates the fabrication process and improves worker safety. This software streamlines prototyping and creates precise measurements. It saves time and effort by integrating computer-aided design, allowing fabricators to identify potential errors prior to production.

It can be integrated with oxy-fuel, plasma and laser cutting techniques for minimal waste, safety and efficiency. Computer-aided manufacturing makes the cutting process easier for operators and creates perfect finishes. It also helps fulfill regulatory requirements for safe operation.

Innovative cutting technologies allow you to create quality finishes with speed and power. At Meritus Gas Partners, we partner with the best in the business to bring you reliable welding and cutting equipment. We’re passionate about helping businesses save money on hard goods, gases and consumables.

Visit any of our locations near you or contact us today and let us help you compare gas-cutting techniques to find the right combination of products to increase your process’s efficiency and quality.