Both electrodes and filler materials play a critical role in ensuring the safety and efficacy of the welding process. There are many options to consider, and the best choice for you will depend on your specific welding project and environment. Below, you can discover the essentials of welding electrodes and filler materials to help streamline your process.

An electrode is a conductor that enables electric current to pass through it. In welding, it creates an electric arc, which builds up the necessary heat to melt the base of the metals you want to join together. Different welding electrodes can affect the mechanical properties of a metal.

Additionally, electrode coatings create a gas shield around the welding arc zone, preventing it from becoming contaminated with oxygen and nitrogen. Without electrodes, oxygen can remove alloys and cause porosity, while nitrogen can cause brittleness, low ductility and corrosion.

If impurities like sulfur get into the welding arc, they can damage the weld deposit and affect its corrosion resistance. By stabilizing the arc, electrodes lower the chances of wide voltage fluctuations. They also reduce attractive pressure and surface tension, creating a sturdier finish. There is also less splatter, which improves visibility and reduces the likelihood of injuries.

You can choose between consumable electrodes and non-consumable electrodes. Consumable electrodes are “consumed” when welding. In other words, they melt and become part of the welded joint. Non-consumable electrodes aren’t “consumed” during welding. They don’t melt and can be used to conduct current in the arc. Tungsten electrode materials are the main non-consumable option.

Understanding the different types can help you choose a suitable electrode material:

Bare electrodes are wire compositions typically used when welding manganese steel and other applications where coated electrodes aren’t suitable. This electrode typically has no coatings besides the bare electrodes used for wire drawing. Bare electrodes have a minor stabilizing effect on the arc but don’t have any specific consequences.

Light-coated electrodes are either dipped, sprayed, tumbled or washed to retain a definite composition that improves the arc stream. These welding electrodes can alter the surface tension of molten metal, converting globules into smaller ones. This streamlines the movement of the molten metal by making the process more uniform.

The coating also reduces the oxide and phosphorus levels and improves arc stability using readily ionized materials. Light coatings do generate slag, but it’s quite thin.

These electrodes have a coating with a definite composition. They’re typically manufactured with two main coatings:

Sometimes, you may find a heavy-coated electrode with a combination of both mineral and cellulose coatings. These electrodes work well with steel, cast iron and other hard surfaces.

This non-consumable electrode has low current capacity and low resistance, so it’s best for less critical applications. It’s also green-tipped and offers 99.5% purity.

With 0.3-0.5% zirconium, these electrodes have alternating current power that works better than pure tungsten. This electrode is typically used to weld aluminum with an alternating current.

Delivering 1% and 2% thorium, these electrodes are often considered better than pure tungsten. They have increased arc stability, improved arc starting and a greater electron output. These electrodes also hold better carrying capacity and have a longer life.

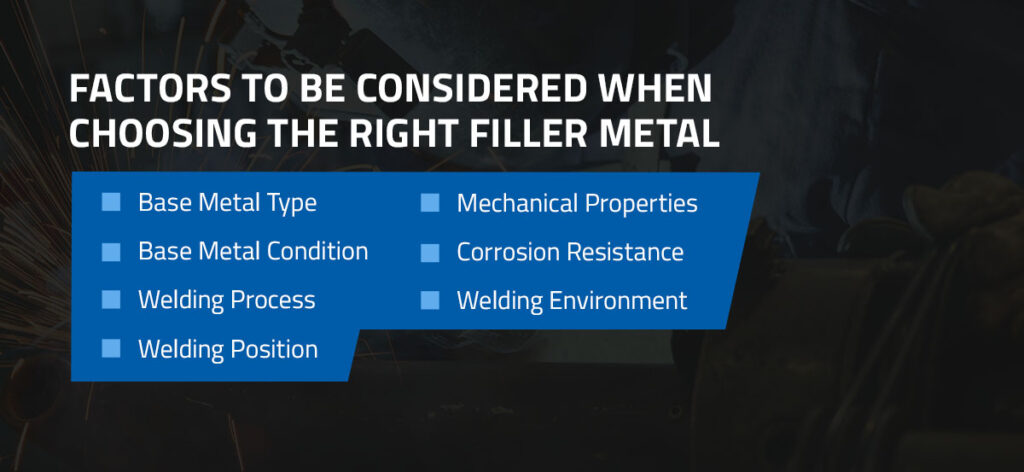

Filler metal is melted during welding to fill the gap between the two base metals. It helps strengthen the weld joint and maintain metallurgical features. Filler metals come in many forms, including wires, rods and powders. They have a powerful impact on the static and dynamic properties of welded joints. Many factors must be considered when choosing the right filler metal, including:

The base metal you’re working with will determine the type of filler metal to use. Consider the filler’s compatibility with the base, as different metals and alloys work best with certain fillers. For example, if you’re working with a steel base, you should use a filler that’s also steel to ensure compatibility. Using the right filler ensures a strong weld.

Look at the condition of the base metal. Note any defects or corrosion and pay attention to cleanliness. If you notice any weaknesses, ensure you match the chemical composition of the base to the filler.

The filler metal should match the welding process and the types of welding tools you plan to use. Metal inert gas welding, also known as gas metal arc welding, and tungsten inert gas welding, also known as gas tungsten arc welding, are two common welding processes that require varying fillers.

Certain filler metals move better in different positions. Determine whether you’ll use a horizontal, overhead, vertical or flat welding position. Welding in a flat position is the most economical option, but certain fillers can make out-of-position welding less challenging.

Some fillers perform better than others in terms of ductility, hardness and strength. For example, powders typically perform well when working with harder-to-reach areas like corners.

In some applications, like aerospace and food processing, corrosion resistance is essential to prevent serious damage. In order to maintain the strength and corrosion resistance of the weld, you’ll want to pick a filler metal with the correct alloying elements.

The welding environment should determine the filler metal. Temperature and chemicals can degrade the weld and promote corrosion to build up inside. Choose fillers with superior heat resistance to prevent welding defects in high-heat surroundings.

Properly storing and handling welding materials are crucial to ensure they’re kept in optimal condition. Following a welding safety guide helps you maintain performance and create quality welds.

High temperatures and excess humidity can negatively affect the flux and coatings on electrodes. To safeguard product efficiency, store welding equipment in a dry, controlled area and ensure consistent temperatures and humidity levels. You can also follow these crucial tips:

Understanding welding electrodes and filler materials is an essential part of the welding process. Meritus Gas Partners works with a range of suppliers to stock many of the hard goods you need to streamline your welding approach for maximum metal fusion and weld longevity. When you work with one of our partners, you can find ways to lower welding costs and increase your throughput with the right materials.

If you’re looking for quality welding materials from experts in the field, contact a Meritus Gas team expert today. Interested in visiting one of our partners’ retail locations? Find a distributor near you, and let us help you select the right combination of equipment and consumables for your short- or long-term welding needs.