In today’s industrial landscape, compressed air, often called the silent workhorse, is the driving force behind various tools, revolutionizing industries across the board.

Compressed air tools, or air-powered tools, are present in sectors ranging from construction and manufacturing to automotive and woodworking. Tools that use compressed air have the potential to bring efficiency, precision and power to tasks that would otherwise be laborious or impractical.

This article covers a significant list of compressed air power tools and the pivotal roles they play across various industries.

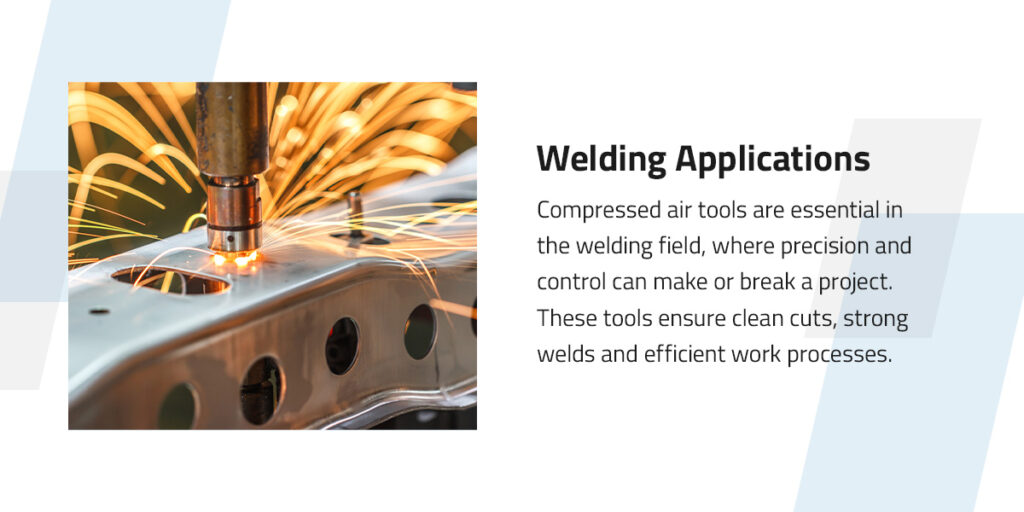

Compressed air tools are essential in the welding field, where precision and control can make or break a project. These tools ensure clean cuts, strong welds and efficient work processes. By harnessing the power of compressed air, welders can achieve excellent results.

Here are a few air-powered tools that find their niche in the welding industry:

Shop Welding Equipment at a Location Near You

In the fast-paced automotive repair and maintenance world, efficiency and precision are crucial. Compressed air tools are the driving force behind essential equipment that keeps vehicles running smoothly. From speedy tire changes to impeccable paint finishes, these tools play a crucial role in maintaining the reliability, safety and design of vehicles on the road.

Here are many examples of air-powered tools in the automotive industry and their invaluable roles:

Compressed air tools require a reliable air source, and garage air compressors deliver the necessary power for various automotive tasks. Garage air compressors power numerous air tools, from impact wrenches to pneumatic drills, making them indispensable in automotive workshops.

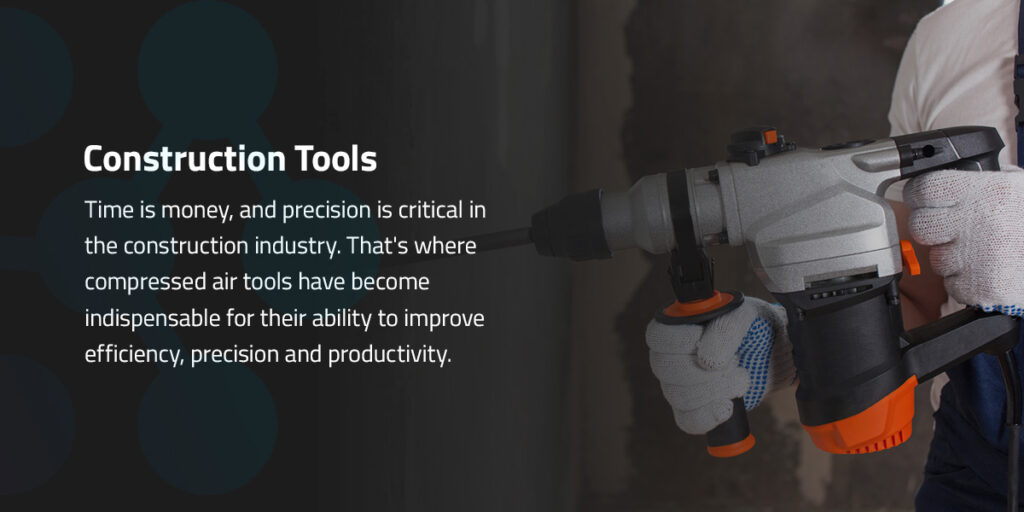

Time is money, and precision is critical in the construction industry. That’s where compressed air tools have become indispensable for their ability to improve efficiency, precision and productivity. From securing wooden frames to breaking through solid concrete, these tools significantly impact the speed and quality of construction projects.

These are essential compressed air power tools used in the construction industry:

Construction sites require a reliable source of compressed air to power many tools. Air compressors deliver the necessary air pressure and volume. These compressors enable the operation of various compressed air tools, from nail guns to jackhammers.

In the industrial sector, compressed air power tools are pivotal in optimizing productivity and maintaining high-quality standards. Air-powered tools can help drill components precisely and seamlessly finish surfaces, offering unparalleled versatility and efficiency.

Here, we explore essential compressed air tools that have become indispensable in the industrial realm:

Industrial air compressors provide a reliable source of compressed air to power various tools and machinery throughout factories. These compressors support various compressed air tools and processes, from assembly lines to quality control.

Compressed air tools are ideal for many home improvement projects, whether users are tackling a major renovation or working on smaller projects.

Here’s a look at essential compressed air tools in home improvement:

Air compressors are a versatile addition to anyone’s personal toolkit, ideal for everything from inflating tires and cleaning surfaces to running pneumatic tools.

The versatility and reliability of compressed air tools make them invaluable in various professional fields. Here are other tools powered by compressed air and their respective industries:

Compressed air tools offer numerous advantages across various industries.

Compressed air-powered tools offer a high power-to-weight ratio. Despite their lightweight design, these tools deliver substantial torque and power output. This means users can handle heavy-duty tasks without experiencing excessive physical strain. This may enhance productivity and minimize operator fatigue, making compressed air power tools an excellent choice for tasks requiring power and precision.

One of the primary advantages of compressed air tools is their adaptability, as users can perform various tasks by simply switching attachments or accessories. This flexibility can simplify work processes and ensure a single set of tools can tackle numerous applications.

Compressed air is often readily available in industrial settings and can be more affordable than other energy sources, such as electricity or gasoline. This affordability translates into reduced operational costs. Furthermore, these tools tend to have a longer life span compared to their electric counterparts, resulting in long-term savings for users.

This combination of cost-efficiency and durability makes compressed air tools an economical choice for various industries.

Compressed air tools are engineered to withstand demanding working conditions, including exposure to extreme temperatures, moisture and dust. This robust construction ensures these tools perform consistently, even in harsh environments.

Users can depend on their compressed air tools for continuous operation, minimizing downtime and maintenance costs. This reliability is crucial in industries where tool performance directly impacts productivity and safety.

When harnessing the power of compressed air tools, it’s crucial to understand and prioritize certain key considerations. These factors ensure your safety and contribute to the efficient operation of these tools.

The longevity and performance of compressed air tools hinge on meticulous maintenance. Regularly inspect your tools for wear, damage or potential leaks. Don’t underestimate the importance of lubrication, which is essential for preventing excessive wear and ensuring smooth operation.

Adhering to the manufacturer’s maintenance guidelines will keep your tools in prime condition.

Safety should always take precedence when working with compressed air tools. Equip yourself with the appropriate personal protective equipment, such as safety glasses or goggles, hearing protection and safety shoes or boots.

Consider setting up screens or shields to safeguard nearby workers from flying debris, dust and excessive noise. Adequate ventilation in your workspace is also essential.

Compressed air tools can generate considerable noise, particularly in confined spaces. Prolonged exposure to high noise levels can result in hearing damage. To mitigate this risk, invest in hearing protection like earplugs or earmuffs.

Additionally, be mindful of the environmental impact of compressed air tools, such as excess energy consumption. Opt for energy-efficient models and remember to turn off air compressors when not in use to reduce unnecessary power consumption.

By keeping these considerations in mind, you can maximize the benefits of compressed air tools while ensuring a safe and eco-friendly work environment.

As we’ve explored the myriad applications of compressed air tools across various industries, it’s evident they hold the key to efficiency, precision and productivity. From automotive repairs to construction projects and welding applications to home improvement tasks, these tools consistently deliver results.

Yet, it’s essential to remember that harnessing the full potential of compressed air tools requires careful consideration. Proper maintenance, safety precautions and environmental awareness are essential components of responsible tool usage. So, whether you’re a seasoned professional or a curious novice, choosing the right tool for your specific application is paramount.

When you’re ready to harness the full potential of compressed air tools, look no further than Meritus Gas Partners. We connect you with the right suppliers, offering a range of industrial gases and compressed air products to support your operations.

Contact us today to discover how we can empower your success through a reliable supply of compressed air and other essential gases.