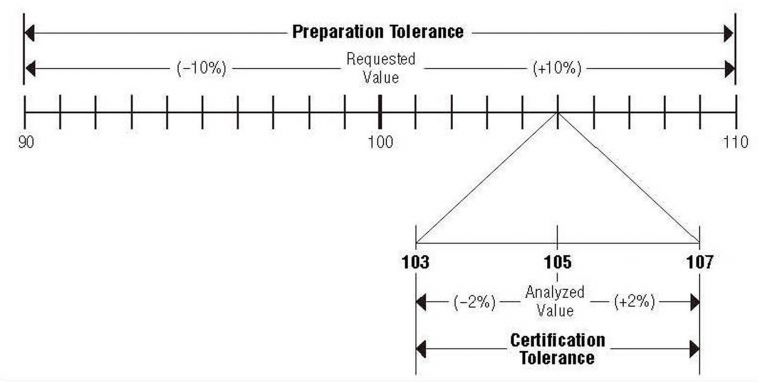

The graphic to follow better serves to illustrate the relationship between mixture preparation tolerance and analytical certification tolerance. This example describes a custom mixture where the requested target concentration of the minor component was 100 ppm. However, an analytical tolerance of +/- 2% relative to minor component concentration was requested. This is a tighter than typical analytical tolerance as mixtures requested at this concentration generally afford an analytical tolerance of +/- 5%. These special requests are routinely accommodated but the request must be clear at time of order confirmation. Simply let us know what your special requirements are.

These mixtures are used specifically for the calibration and audit of Continuous Emission Monitors (CEMs). Global Calibration Gases EPA Protocols are NIST traceable and produced in accordance with the latest EPA specifications found in document EPA 600/R-12/531 (May 2012). Not only do these specifications require an unbroken chain of measurements directly against a NIST SRM or its equivalent, but also a series of quarantine periods between additional analyses that insures the long term stability of the gas mixture. In addition, the repetitive analyses affords sufficient statistical data to insure that the total expanded uncertainty of the results reported on the certificate of analysis will not exceed 1% relative to minor component at the 95% confidence level with a coverage factor of 2 (k=2). Blending techniques are not specified in the Protocol and a method of blending is chosen based on the components of interest and the desired target concentration. Target concentrations are based on the regulated customer’s monitoring requirements and the availability of NIST SRM materials at the desired concentration. A mixture may not be certified as a EPA Protocol mixture unless the manufacturing location has an appropriate SRM or its recognized equivalent on hand. In addition, the manufacturing location must have a current PGVP identification number indicating that the manufacturing location participates in the required audits conducted via the Protocol Gas Verification Program.

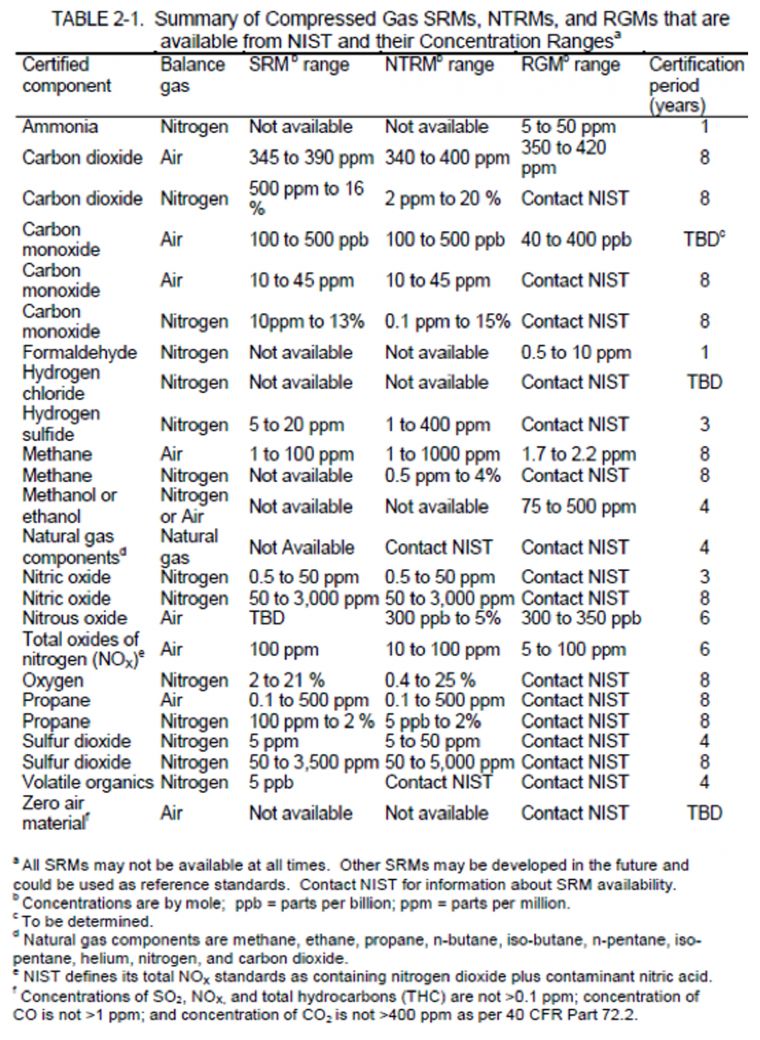

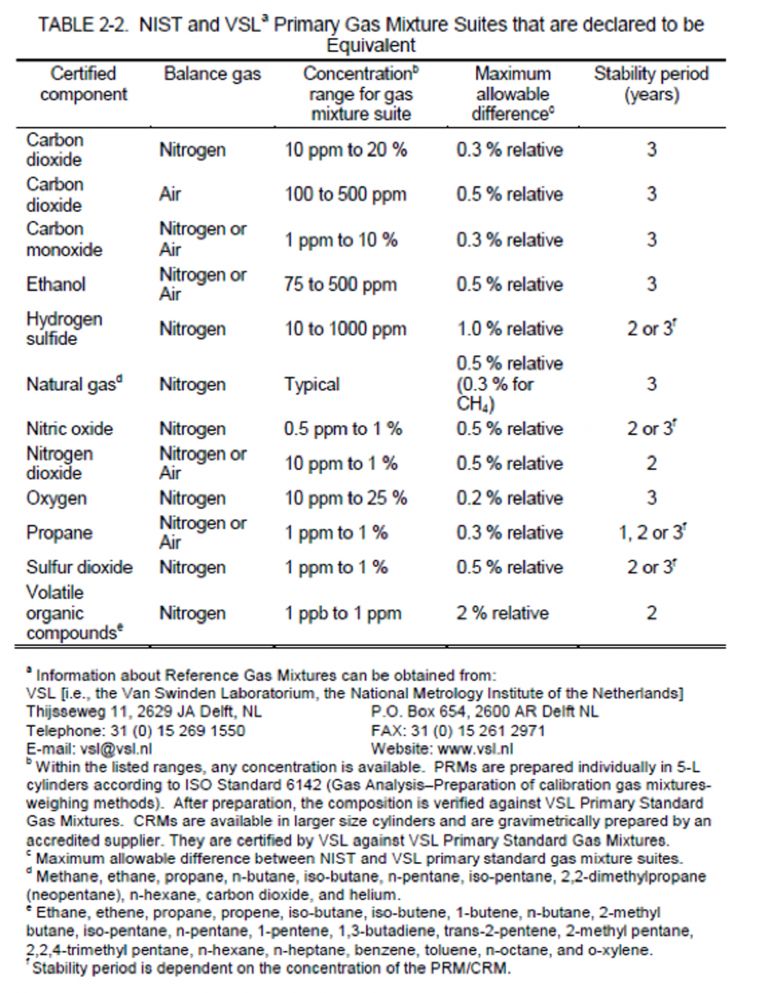

It is very important to note that all custom mixtures cannot be certified as EPA Protocol mixtures. The current protocol document is clear on this. A protocol mix must have the same components as are available as NIST SRM materials or their recognized equivalents. This includes the balance gas in the mix. In addition, the maximum concentration of the minor component permitted to be certified as a EPA Protocol mix must be equal to or less than the concentration of the available SRM material. The following table 2-1 lists the SRM materials available and is excerpted directly from the most current EPA Protocol document. Additional recognized equivalents are listed in table 2-2 which is also excerpted directly from the most current EPA Protocol document. These equivalents are produced by VSL (the National Metrology Institute of the Netherlands) and may be used exactly as permitted for SRM materials in all appropriate areas of the EPA Protocol document.

NTRMs are certified by the National Institute of Standards and Technology (NIST) and are accepted by the Environmental Protection Agency (EPA) as the most accurate standards available commercially. NTRMs are recognized SRM equivalents in the most current EPA Protocol document. The NTRM program was established in 1992 in partnership with the U.S. Environmental Protection Agency and specialty gas companies as a means for providing end-users with the wide variety of certified gas standards needed to implement the “Emissions Trading” provision of the 1990 Clean Air Act. Gas NTRMs are produced and distributed by specialty gas companies with NIST oversight of the production, as well as direct involvement of the analysis. NTRMs can be developed for any pollutant, concentration and balance gas combination for which a NIST primary standard exists. The gas standards prepared according to this program are related, within known limits of uncertainty, to specific primary standards maintained by NIST.