There are many benefits to shipping with dry ice. Unlike wet ice, dry ice sublimes and prevents mess during transportation. It also enables you to keep your products fresh throughout transit. Dry ice is ideal for shipping various items, including food and medical products.

Knowing the regulations and best practices for safely shipping on dry ice, whether transporting it alone or with other products, is essential. This guide will teach you the basic requirements for shipping dry ice, including packaging, labeling and marking, documentation, storage, handling, and safety precautions.

Dry ice is the solid form of carbon dioxide. It’s commonly used as a refrigerant for various industrial purposes, such as medicine and food preservation during transportation. Dry ice differs from wet ice because it turns into gas and evaporates. Dry ice is created by freezing carbon dioxide at -109 degrees Fahrenheit. As it “melts,” it reverts to its gaseous state without becoming liquid.

The United States Department of Transportation (DOT) regulates the domestic transportation of hazardous materials in commerce, including dry ice, while the International Air Transport Association (IATA) provides international guidelines. The regulations provide specific procedures for handling, labeling, packaging and shipping dry ice. They also provide the quantity limit for transporting dry ice by water or air.

To understand hazardous materials regulations, it’s vital to know the table under 49 Code of Federal Regulations (CFR) 172.101. The table identifies the hazard class for each listed material or specifies that the materials are forbidden in transportation. It also provides the material’s proper shipping name or directs you to the preferred proper shipping name, which describes the dangerous goods’ hazardous properties and composition.

The proper shipping name for dry ice is “dry ice” or “carbon dioxide, solid,” and it is considered a miscellaneous class 9 dangerous good with United Nations identification (UN ID) number 1845. Hazard Class 9 materials present hazards during transportation but do not meet the definition of any other hazard class.

Dry ice generates carbon dioxide as it sublimes, which can displace oxygen in the closed environments of an airplane, so it’s best to comply with the shipping requirements. The UN ID 1845 is specific to dry ice and can help in emergencies. For example, it can help the first responders quickly assess the type of hazardous materials.

Another vital piece of information provided in the hazard materials table is the packing group, expressed in Roman numerals. The packing group shows the specified hazard class’s relative degree of hazard. Packing group I indicates a high degree of risk. Packing group II is moderate, while packing group III is low. Although dry ice is a Class 9 hazardous material, the DOT considers it to pose a relatively low degree of hazard.

According to the 49 CFR parts 171-180 regulations, employees who handle hazardous materials should undergo training. This applies to all employees engaged in shipping, receiving, handling or transporting dry ice, regardless of quantity. Complying with these rules and regulations prevents sanctions from the DOT and IATA.

Here is a summary of the six basic requirements for shipping dry ice:

As a requirement, you must label the outermost container with a UN ID number 1845 label, a hazard Class 9 label and the net weight of dry ice in kilograms. The label should be on the vertical side of the box. Regarding the weight limit, the maximum allowable net quantity per package is 200 kilograms.

It’s vital to ensure proper documentation when transporting dry ice. For example, the air waybill or airbill should provide details such as the UN ID number, the number of packages and the net weight in kilograms. There could be additional documentation depending on the carrier and destination. It’s important to ensure you have the proper notation on the paperwork.

The packaging used to transport dry ice should be highly durable. Additionally, the packaging should be securely closed to prevent content loss, which may cause vibration or changes in humidity and temperature.

Dry ice turns into carbon dioxide gas at room temperature, including most storage temperatures. The gaseous escape can cause difficulty in breathing when there is poor ventilation. Use well-ventilated packaging when storing and transporting dry ice.

You should avoid plastics that can turn brittle or porous. Instead, use packaging specifically designed to contain dry ice, like an Expanded Polystyrene foam container for its insulating properties and a sturdy, corrugated cardboard box.

The item must be secured in durable inner packaging so it doesn’t break, puncture or leak into the outer packaging during transport. For example, if the item shipped with dry ice is breakable, you must cushion it to control its movement. When the content leaks, the prospective properties of the cushioning material or outer packaging must remain intact.

Choosing suitable shipping packaging is vital for safe delivery. As mentioned, dry ice releases carbon dioxide gas, which can reduce the amount of oxygen in the surrounding environment. The gas can also build enough pressure to rupture the packaging.

When transporting dry ice, whether by itself or with other items, you must ensure the packaging allows pressure release to prevent it from rupturing. Using outer packaging like jerricans and steel drums and placing dry ice in plastic bags are not recommended.

Quality fiberboard or wooden boxes are appropriate packaging for shipping dry ice. Additionally, use an insulated container that can withstand freezing temperatures. You may place a layer of styrofoam in dry ice shipping boxes for insulation, but the styrofoam should not be sealed or airtight. Polyurethane foam packaging can prevent dry ice packaging from contacting the container walls directly — direct contact can cause leaks and damage.

Another point to note is that absorbent materials shouldn’t react with the contents of the container. However, you don’t need to worry about this if the inner packaging is secured to remain intact during normal transport conditions. As stated, you want to prevent the inner and outer packaging from breaking or leaking.

The shelf life of dry ice can vary depending on the handling. The amount of dry ice, the thickness of the styrofoam, the amount of space in the box and the area where it’s being kept are all aspects you should keep in mind when deciding how to ship dry ice. For example, if the destination is far or you expect long transit times, you may purchase more dry ice and use thicker styrofoam for the packaging.

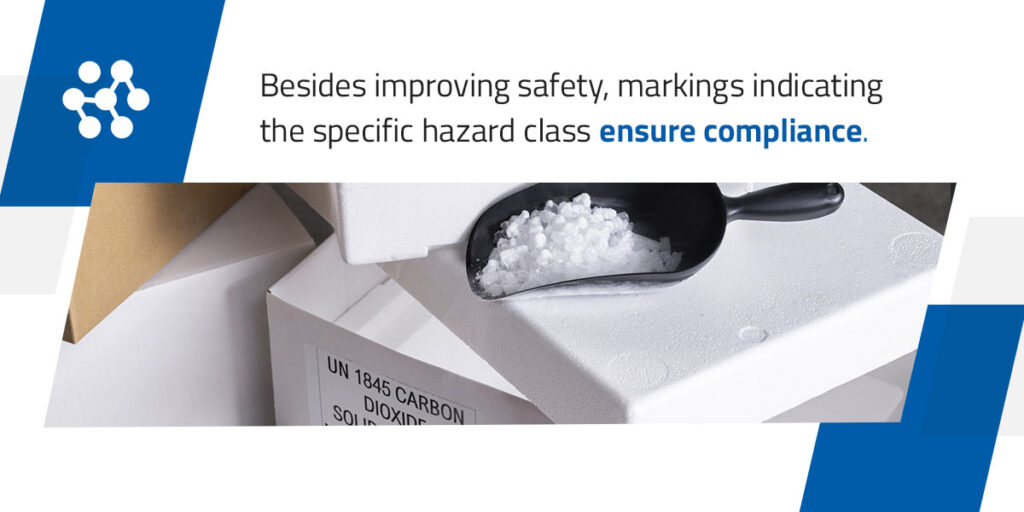

Labeling and marking packages that contain dry ice is essential to ensure optimal safety during transportation. This identification tells anyone who comes into contact with the packaging that it contains hazardous materials. Therefore, you must label the package with the appropriate warnings and provide instructions for proper handling. Additionally, the label must include a description of the content and the weight.

Besides improving safety, markings indicating the specific hazard class ensure compliance. They show the risks of handling the package, so securely attach them to the packaging and ensure they can withstand the elements. Markings should be legible and accurate to eliminate confusion or mishandling during storage and transportation.

Markings on the package should contain specific information, including:

The shipper’s and recipient’s name, address and contact information must be durably marked. Remember to use the minimum marking sizes on all dry ice packaging.

Again, comply with IATA Dangerous Goods Regulations on shipping requirements for shipping dry ice. The air waybill and dangerous goods declaration are relevant when transporting dry ice by air. Having just the airbill is usually enough for domestic shipments. Other supporting documents to include, especially for international shipments, include:

As with any hazardous material, you must ensure you and anyone in your facility handling dry ice knows how to do so properly. There are essential safety precautions to consider when working with dry ice, which generally include the following.

Dry ice hazards can be broken down into three categories:

There are many forms of dry ice, including blocks, pellets and flakes. Each state poses health hazards, so handling them with care is essential. Here are two tips to help you stay safe:

If anyone in your facility comes into direct contact with dry ice while handling it, you should know how to address this. Treating dry ice burns is similar to treating regular heat burns. Generally, it’s best to contact a medical professional immediately to ensure the burn isn’t too severe. Always ensure that anyone working with dry ice understands the procedures for alerting someone they’ve come into contact with the product.

Always keep dry ice in well-insulated areas. Refrain from storing dry ice in confined locations with limited ventilation, like environmental chambers, walk-in registrators and cold rooms. As stated, don’t store dry ice in a tightly sealed container with no ventilation. Ensure dry ice is monitored properly when stored in open areas to avoid accidents.

The same applies when disposing of dry ice. Place dry ice in a well-ventilated area at room temperature and wait for it to sublimate. Avoid disposing of unwanted dry ice in trash cans, chemical waste containers or other waste cans. Disposing of dry ice in a sink is also not advised — the temperature difference can destroy plumbing systems.

Use appropriate containers and methods when packaging dry ice for transportation. If you receive swollen or bulging containers or suspect improper packaging, place them in a secured location and take the appropriate steps to mitigate the issue.

The labeling and marking on the packaging inform the recipient of the package’s contents. However, it’s best to include additional information to ensure optimal safety. Provide clear instructions for safe handling and disposal and ensure a qualified person receives the package.

Always track your dry ice shipments to ensure timely deliveries. This will allow you to address delays and other issues with the carrier. Additionally, you should monitor the temperature levels throughout transit to ensure safety.

Dry ice regulations cover labeling, marking, packaging, storing and safely handling dry ice. The goal is to protect anyone who comes into contact with the material. Dry ice has many benefits, including food and medicine preservation. It allows you to ship your items at the required temperatures without contaminating them.

Meritus Gas Partners works with multiple partners to supply clients with a range of welding and gas services, including food and beverage gases like dry ice. If you need dry ice for your operations, we can help. Contact us today, and we’ll work to pair you with the right gas supplier for your dry ice requirements.