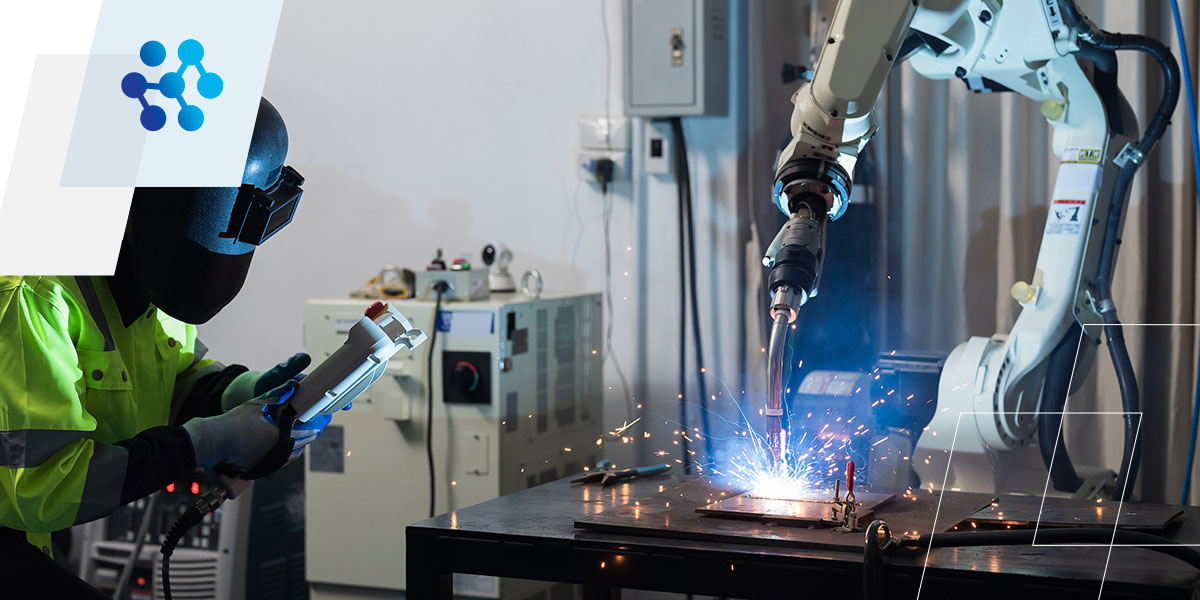

Challenges and trends in the welding industry demand change to stand out among the competition and grow one’s business. Whether you have a shortage of human welders or require increased precision, a cobot welder is an automated welding solution that may be able to help you address specific welding issues for your business.

In this guide, you’ll learn everything you need to know about what cobot welders are, how they work and how they can benefit you.

Collaborative robots or cobots are robots that work with other cobots or humans to complete a particular task or application. These robots typically offer effective mobility, ease of use and enhanced accessibility.

Cobot welders are collaborative robots with effectors and fixtures to produce high-quality welds. These welding machines can easily execute complex projects with little supervision. A cobot welder features an arm, welding system, welding gun, ancillary tools and sensors, safety equipment and a programming interface.

These machines are compact solutions that are ideal when you have various types of workpieces that require welding. By using a cobot welder, businesses can automate the welding process while increasing productivity and accuracy. Many smaller businesses that lack the means to hire more welders may benefit most from this solution and can instead train their current staff to program the cobot welder to execute the welding process.

Given that cobots are more collaborative in their fundamental abilities, people can work in close proximity to these machines. Their main objective is to enhance data capabilities, human strength and precision.

Training the machine properly is essential to ensure proficiency. Here are the steps you can take to train or program a collaborative welding robot:

Generally, you shouldn’t have to tweak the program unless you need to make adjustments to the path later. Test the cobot over time and ask for your employees’ input to see how you might be able to create the perfect system for your workspace.

The advantages of using cobot welders make them a popular welding solution across industries associated with aerospace, heavy equipment, automotive and appliances. Cobot applications for businesses in these industries include laser welding, plasma welding, arc welding and more.

Here are five benefits that this type of welding automation has to offer.

While even the most skilled and efficient welders need to take breaks, cobot welders can execute long and mundane tasks without pause and sometimes even faster than a human. This ability allows companies to upscale their production processes and employees to prioritize other, more urgent tasks. It also creates room for companies to take on more clients during peak seasons, leading to increased profitability.

Many welding companies may find it challenging to find skilled welders with the necessary qualifications. According to the American Welding Society, around 360,000 welders will be needed by 2027.

When labor shortages arise, companies can use cobot welders to lessen the strain on under-staffed welders and increase productivity. While it’s unlikely that cobots will ever fully replace human welders, given that some welds are simply best suited for human completion, these machines can help shops remain efficient during these shortages.

While the immediate costs of collaborative welding robots can be high, the investment may be worth it in the long run when you consider how much more efficient they’ll make your process. By allocating tedious but necessary tasks to the cobot, you can free up your staff to focus on more complex, intricate tasks that allow them to use their best skills.

As a result, you complete simple processes faster, allowing your team to take on more projects and create more profits. Depending on your business, a cobot can eventually pay for itself, possibly sooner than you think.

Regardless of how skilled a welder is, they can still be inaccurate, and some welds will be slightly different from one another. With cobot welders, you can be sure that the machine will always perform repetitive tasks similarly, resulting in more accurate and uniform welds.

Another benefit of cobot welders is their reactive sensors, which help them quickly detect workers and react accordingly to keep them out of harm’s way. They also have collision features that allow them to slow their movement or shut down completely to avoid impact with an object or person. Unlike traditional robots, cobots can seamlessly work alongside your crew of employees, creating a safe and balanced work environment.

Using cobots for welding can be significantly beneficial as a long-term investment, and these machines are easy to use and program, making them a worthwhile addition to your company. Still, industry knowledge and an understanding of how to effectively implement cobots are essential to help maximize your success.

Meritus Gas Partners has suppliers in our network with different cobot solutions to help you choose the best machines and components to match your welding needs. For example, the MOD-WELD Cobot from APT Manufacturing Solutions is a next-generation product with top-of-the-line components. To get started on your collaborative welding robot journey, request a quote from us or find a partner near you today!