Welding is an important practice in industries like construction and manufacturing. However, it comes with various hazards that can impact the health and safety of welders and others nearby. Dangerous compressed gases can explode or leak when handled incorrectly. Gases can be chemical and mechanical hazards and can be flammable, explosive, acidic, corrosive, reactive and poisonous, depending on the environment they’re in and how people handle them.

In this guide, we provide you with all the information you need for handling dangerous gases in the best way possible, from gaining the appropriate training on how to handle, store and secure dangerous gases to attaining leak detection systems and implementing an emergency plan. Learn essential safety tips for dealing with hazardous gases below.

One of the most critical safety tips for handling dangerous gases is attaining the correct training for it. This includes completing a laboratory training program, knowing the various hazardous materials and risks of processes, and working according to a hazard control plan. Knowing how to handle dangerous gases is important because all gases have unique properties to consider in terms of handling, storage and use.

Four factors to consider when evaluating properties include:

Personal protective equipment (PPE) plays an essential role in ensuring safety while working with compressed gases. All gases are different, meaning welders may need varying PPE. Some PPE workers need to use when working with or around dangerous gases include:

When dealing with cylinders, it’s crucial to understand the best practices for handling them and keeping them organized in the workplace. The correct personnel must stamp and stencil each cylinder to identify the contents. These labels will help distinguish whether the gas is toxic, flammable or corrosive. If the supplier sends an unidentified gas cylinder, you must send it back for them to identify. It’s also best to avoid identifying them by color or the interchangeable label on the cylinder cap.

Further, you should maintain and implement the following practices:

Long exposure to dangerous gases can cause neurological and physical damage or result in fatality. Leak detectors can help reduce the chances of this happening by clearing the welders’ breathing space of hazardous gases.

Gas detectors can sense carbon monoxide and other gases without taste, odor or color in their natural states. An approved leak-detection fluid or non-detergent soap solution can also help detect leaks from a regulator or hose.

You can regularly monitor gas levels during welding processes by installing a fixed gas detection system.

When exposed to hot surfaces or flames, compressed gases easily explode or cause fires. This possibility makes it essential for those who handle dangerous gases to understand the correct safety measures and store them in cool, dry and well-ventilated spaces. Additionally, workspaces as a whole should be well-ventilated to protect employees.

Another important factor is to establish your emergency contact numbers. A local exhaust ventilation system is most effective for high-intensity welding activities and dispersing highly toxic gases. This system removes contaminated air through devices like filters, hoods, fans and ducts. Natural ventilation systems use fans and blowers for low-intensity welding activities and mainly rely on airflow through vents, doors and windows.

An effective ventilation system is especially important because when airflow goes in the wrong direction, it can create backflow, causing an increased gas density in the workspace. This event can also happen even with an exhaust fan, making it essential to conduct regular maintenance.

Here are some best practices for welders to follow:

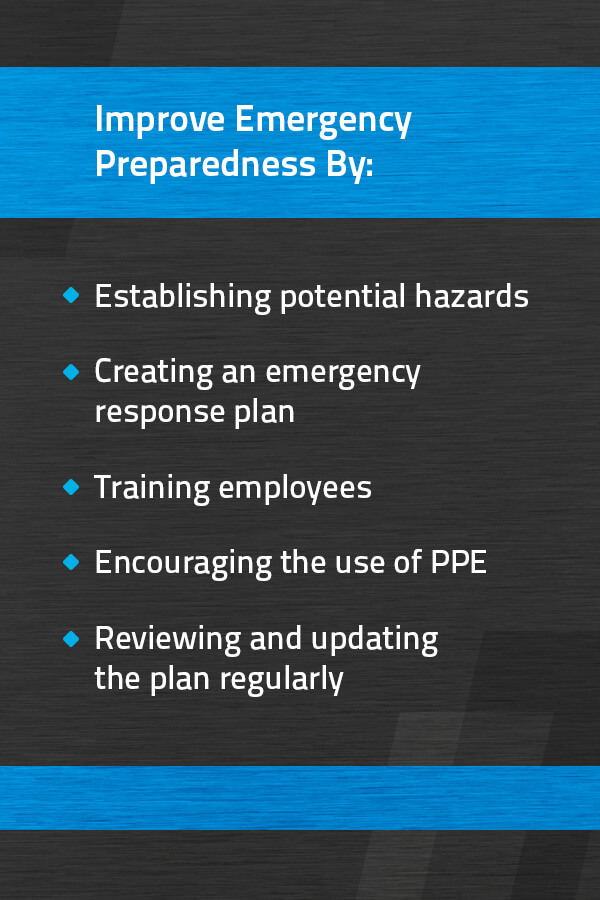

It’s important to put an emergency procedure in place to reduce injuries, accidents and fatalities in the workplace. This procedure should involve establishing exactly what constitutes an emergency and what workers should do in the event of an emergency. You can improve emergency preparedness by:

Additionally, an individual emergency procedure a worker may follow includes:

In the case of gas inhalation, individuals should leave the facility immediately to go outside and call for emergency services. Then, they should document the incident according to procedures.

Determining compressed gas compatibility is an essential part of maintaining dangerous gas safety. You can do this by reviewing manufacturer instructions and consulting with a safety professional.

In most cases, you’ll need to store incompatible gases in separate, well-ventilated storage areas with proper labeling and handling instructions attached. Storing gases away from heat sources like direct sunlight, heaters and furnaces is important because heat can make gases expand in the cylinder, increasing the pressure and causing the cylinder to burst.

At the same time, you should separate incompatible gas cylinders because they can react dangerously when you store them together. You can use proper signage by labeling the storage area and cabinet to ensure workers know the potential risks and how to handle these gases properly. Workers can also use the appropriate handling equipment and tools, such as fittings, connectors and the correct handling instructions.

Improper disposal of containers for dangerous gases can easily endanger the environment. Some proper disposal regulations for empty or expired gas containers you should follow include:

Handle the cylinder with care since residual pressure can be dangerous. Avoid refilling and mixing gases, as this could cause an explosion.

The most important aspect of maintaining these safety tips for dangerous gases is consistently monitoring gas handling practices, regularly reviewing and updating safety protocols, and encouraging workers to report any safety concerns. Regular safety inspections and equipment checks can also ensure all tools, such as detectors, gas appliances and containment vessels, function properly.

This is especially important because you need working equipment with uncompromised functionalities to keep workers safe during emergencies. Gas monitoring systems should have the following functionalities to improve dangerous gas safety:

Hazardous compressed gases require careful attention and compliance with strict safety rules. They require workers to have skilled training to handle gases appropriately, wear personal protective equipment, and take crucial precautions, such as leak detection and gas monitoring systems, to ensure everyone’s safety.

That’s why we recommend a proactive approach to dangerous gas safety to prevent accidents and promote a safe working environment. With an experienced gas supplier like Meritus Gas Partners, you can be sure to receive trusted information about safe gas handling and storage. We also provide qualified representatives to assist you with the supply of compressed gases and customized solutions to improve safety.

If you’re interested in working with one of our partners for your welding needs, we encourage you to contact a local distributor today.